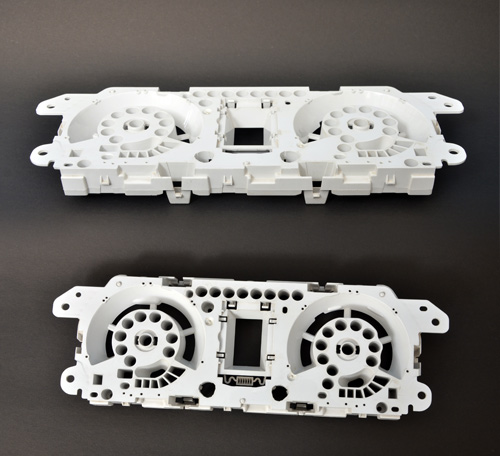

Innovative Moulds & Dies have a fully equipped tool room facility. We have the machinery like, Vertical Machining Centre, Electric Discharge Machine, Surface Grinding, Conventional Milling, Conventional Lathe, Ultrasonic polishing machine with all necessary supporting accessories.

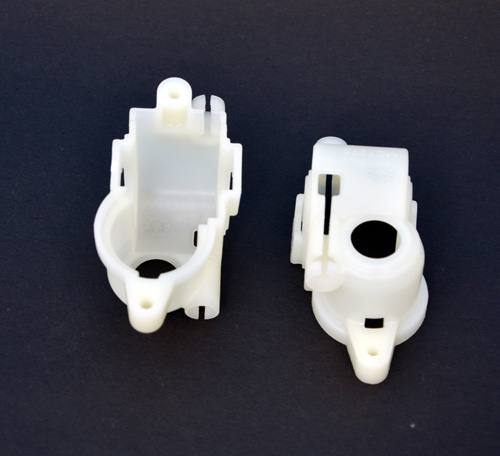

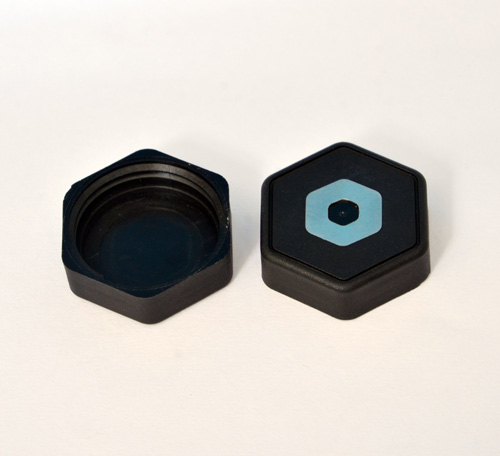

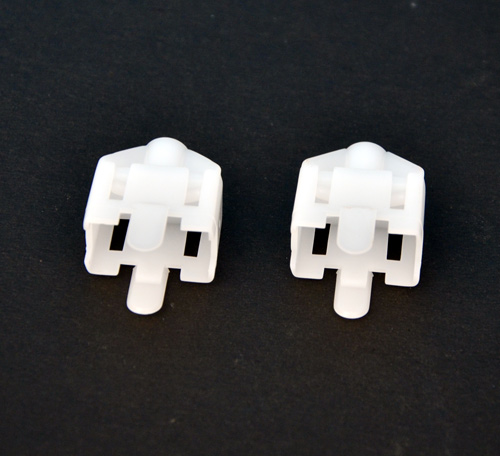

In the area of production we have Injection moulding machine from 50Tonnage to 300Tonnage with necessary ancillary items like, Hopper Dryer, Owen, Loader, Mould Temperature Controller and Chillers etc.

In our assembly area we have Ultrasonic Polishing machine, 10bar capacity Immersion Testing machine, 5bar capacity Immersion machine, Hot plate, Bobble Tester, etc.,

For inspection we have Co-Ordinate Measuring Machine, Video Measuring machine and all necessary precision measuring equipment.